Modern pickleballs are crafted through either rotational molding (creating seamless one-piece balls) or injection molding (producing two-piece balls with seams). You’ll find indoor pickleballs made from softer polyethylene with 26 larger holes for controlled play, while outdoor versions use tougher polypropylene with 40 smaller holes to withstand harsh conditions. Each ball undergoes rigorous quality testing for weight (0.78-0.935 oz), diameter (2.87-2.97 in), and bounce height. Discover why these precise manufacturing differences dramatically impact your game performance.

Key Takeaways

- Modern pickleballs are made using either rotational molding (one-piece) or injection molding (two-piece) manufacturing processes.

- Indoor pickleballs utilize softer polyethylene plastic with 26 larger holes, while outdoor versions use tougher polypropylene with 40 smaller holes.

- Rotational molding creates seamless one-piece balls with more consistent performance, while injection-molded two-piece balls are less expensive.

- Manufacturing includes precise quality control, ensuring proper weight (0.78-0.935 ounces), diameter (2.874-2.972 inches), and bounce height.

- Advanced pickleball production now incorporates specialized polymer blends and UV-resistant coatings for improved durability and consistent performance.

The Evolution of Pickleball Construction Materials

While you might think pickleballs have always been the same, they’ve undergone a remarkable transformation since the sport’s inception. Today’s balls are crafted from specialized plastic polymer blends that balance bounce and flight characteristics.

You’ll notice a clear distinction between indoor and outdoor varieties. Indoor pickleballs use softer plastics like polyethylene that respond like a perfectly risen soufflé—yielding just enough when struck. Outdoor versions incorporate tougher polypropylene, similar to how a well-seasoned cast iron pan withstands intense heat.

The manufacturing process has evolved dramatically too. Injection molded balls feature distinctive seams that affect trajectory, while newer rotational-molded versions offer seamless construction. These advancements haven’t just improved durability—they’ve created balls that respond consistently to your touch, regardless of playing conditions.

One-Piece vs. Two-Piece Manufacturing Methods

As you explore the world of pickleball equipment, you’ll discover that manufacturing methods greatly impact how your ball performs—much like how different cooking techniques transform the same ingredients into entirely different dishes.

One-piece pickleball balls are crafted through rotational molding, creating a seamless design with consistent 2mm thickness throughout. This process yields predictable performance and consistent bounce that tournament players crave. Two-piece balls, however, emerge from injection molding with a distinctive seam that increases wall thickness by 30%.

While two-piece balls cost less to produce—similar to choosing pre-packaged versus scratch-made in cooking—their softer plastic composition often delivers less predictable play. The one-piece construction, exemplified by the Cheetah® M45, offers superior durability with less warping, making it the premium choice for serious players.

Polymer Science Behind Modern Pickleballs

The molecular structure of your pickleball’s polymer blend determines its performance much like ingredients determine a recipe’s final taste. Manufacturers primarily use two plastic polymers: polyethylene for indoor balls and polypropylene for outdoor pickleballs.

When you’re slicing shots on indoor courts, you’ll appreciate how polyethylene creates a softer, more controllable ball with fewer, larger hole patterns. It’s like using a delicate flour that yields perfect texture. For outdoor play, polypropylene delivers the durability you need—think of it as the hearty base that withstands all conditions.

The manufacturing method also influences performance. Rotational molding produces seamless balls with consistent flight stability, while injection molding creates two-piece designs that offer different playing characteristics. These polymer science advancements guarantee your pickleball performs exactly as you expect, regardless of where you play.

Indoor vs. Outdoor Ball Design Differences

Stepping onto different pickleball courts demands distinctly different ball recipes for ideal play. You’ll notice indoor pickleballs feature a softer plastic blend with 26 larger holes—think of them as aeration points that enhance control and reduce drag, allowing you to serve up precision shots with satisfying spin.

In contrast, outdoor pickleballs are crafted from heartier plastic stock with a thicker 3mm “crust” versus the indoor’s 2mm thickness. Their 40 smaller holes are perfectly portioned to minimize wind interference while maximizing durability. The result? A flight performance that withstands Mother Nature’s menu of challenges.

When selecting your ball, remember that indoor varieties deliver a predictable, controlled bounce, while outdoor versions offer resilience and consistency in unpredictable environments—each precisely engineered for its intended court “kitchen.”

The Critical Role of Hole Patterns and Spacing

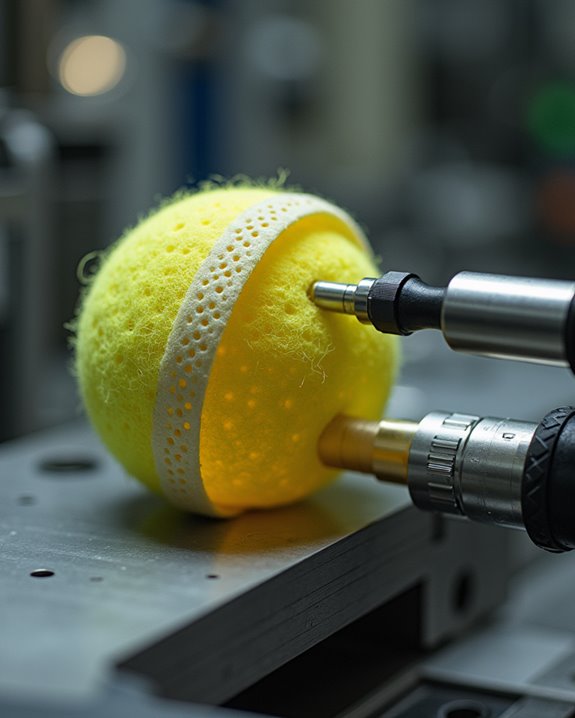

Precisely perforated across each pickleball’s surface, hole patterns serve as the secret sauce in your game’s recipe for success. When holes are drilled into these spheres, manufacturers follow exacting specifications that dramatically affect how your shots will perform.

You’ll notice indoor pickleballs feature around 26 larger holes, creating a ball that’s easier to control—like folding ingredients gently into your batter. Outdoor play demands resilience against wind, so these balls come equipped with approximately 40 smaller holes for stability in gusty conditions.

This careful hole design isn’t random; it’s a calculated formula ensuring proper aerodynamics and the regulation bounce height (30-34 inches from a 78-inch drop) required by USA Pickleball. The precise spacing directly determines your ball’s flight characteristics, affecting everything from speed to spin.

Material Hardness and Its Impact on Play Performance

Beyond those perfectly placed holes lies another key ingredient in your pickleball’s recipe—the hardness of its materials. The material used to craft your Pickleball Ball greatly influences how it performs on the court. Measured on the Shore D Durometer scale (40-50), hardness determines whether your ball serves up speed or control.

Players often prefer softer balls (around 45) for better control and comfortable play. Like folding egg whites into a soufflé, manufacturers blend plastics to achieve the perfect consistency. Wall thickness (typically 2mm in one-piece balls) guarantees a stable flight path and predictable bounce.

When a ball’s too hard (above 50), it’ll crack under impact like an overcooked meringue. Too soft, and it won’t maintain its shape. The sweet spot delivers that satisfying “pop” you crave!

Quality Control in Professional Pickleball Production

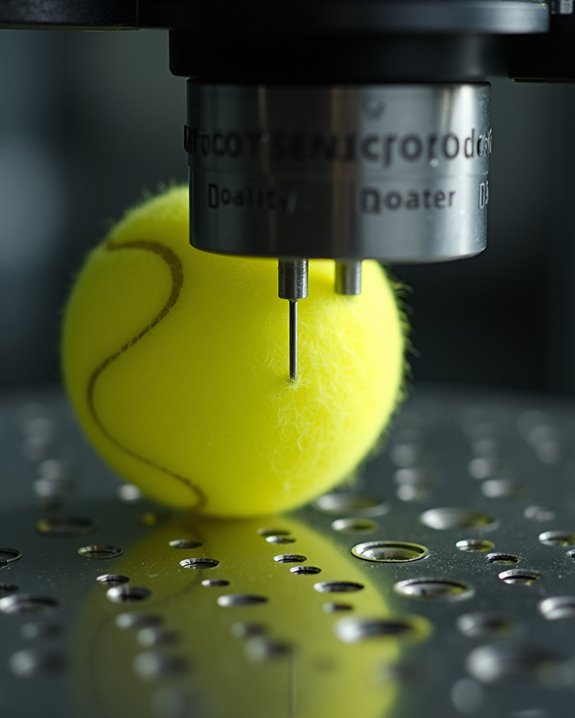

While your pickleball might look simple, it passes through a quality assurance process as rigorous as judging a five-star soufflé competition.

Each crisp, perfectly-balanced ball is meticulously weighed (0.78-0.935 ounces) and measured (diameter 2.874-2.972 inches), ensuring consistency you can feel with every smash. Manufacturers conduct drop tests to verify bounce height falls between 30-34 inches when released from 78 inches—much like testing a cake’s spring-back.

You’ll appreciate the inspection processes that scrutinize those uniform hole patterns (26-40 holes precisely positioned). Advanced robotic systems check hole symmetry before welding, eliminating imperfections that would affect your gameplay.

Every professional pickleball earning the coveted USA Pickleball standards seal and manufacturer logo has been thoroughly vetted—guaranteeing you’re playing with nothing but tournament-worthy equipment.

Emerging Technologies in Pickleball Manufacturing

As pickleball continues to simmer in popularity, you’re benefiting from a technological revolution that’s transforming the equipment in your hands. When you plunge into the fascinating world of modern pickleball production, you’ll discover how advanced polymer blends are being folded into the latest pickleball recipes.

Injection molding now incorporates UV-resistant coatings that prevent your pickleballs from “burning” under intense sunshine. These coatings crisp up the rough surfaces for peak grip during play. Meanwhile, carbon fiber paddles are being garnished with noise-dampening materials—a perfect reduction sauce for community courts concerned about noise.

The freshest innovation? Smart paddles with built-in sensors that serve up real-time feedback, helping you perfect your technique like a master chef perfecting their signature dish.

Frequently Asked Questions

How Are Pickleballs Manufactured?

As slick as a whistle, you’ll find pickleballs made through material selection, then shaped via injection or rotational molding. Manufacturing processes guarantee design specifications are met before rigorous performance testing and quality control measures finalize production.

Are Pickleballs Rubber or Plastic?

Pickleballs are made from plastic polymers (PE and PP), not rubber. You’ll notice their design evolution prioritizes durability and consistent performance characteristics across different surfaces and temperatures, all while meeting strict weight regulation standards.

Is There Really a Difference Between Indoor and Outdoor Pickleballs?

Did you know outdoor pickleballs have 40 holes while indoor ones have just 26? Yes, they’re different! You’ll notice variations in surface texture, durability, bounce characteristics, and color choices depending on your playing conditions.

Are Pickleballs Just Wiffle Balls?

No, they’re not just wiffle balls. Despite similar appearances, pickleball history shows distinct equipment differences from wiffle ball origins. You’ll notice variations in weight, durability, hole patterns, and performance designed specifically for pickleball popularity and game strategies.